Custom Watch Manufacturer--DESIGN AND PATTERN MAKING

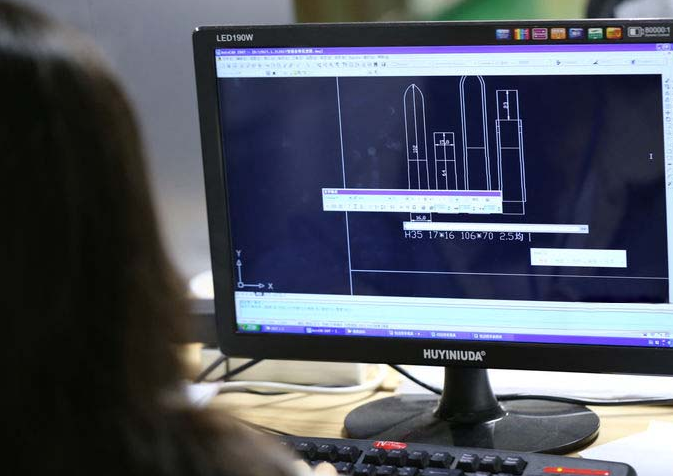

Different brands, different styles, and different sizes of watches require different strap sizes. In order to match, detailed designs must be made on the computer and patterned before actual production.

The pattern-making is divided into two types, one is the manual pattern making, which uses a carving knife to carve out the template of the strap, which is suitable for small batch customization. The disadvantage is that the production speed is slow and the process is complicated.

The other is the die cut, which is made according to the previous design data, which is suitable for mass production.

In the early days, consumers pursued “manual”, and the deeper level was to pursue ‘more refined’ products, because the early large-scale industries were difficult to achieve refinement.

Consumers basically want more sophisticated products, and the use of the die cut perfectly meets this requirement. Including the small pieces of leather produced by Hermès, they are all processed by die cut. If a person tells you that his watch strap product does not use the die cut, there is only one situation, that is, the order is too small. Because the cost of developing die cut is much higher than using a one-time manual pattern making, and the data of each strap is different.

The elbow strap suitable for formal watch is cut with a customized high-precision die cut, and the lines at the interval are smooth.